Emerging Trends in Liquid Nitriding Technology

Our team of HEF Group engineers is engaged in R&D activity to advance liquid nitriding technology, including new and innovative nitriding chemistries that can be used effectively at lower operating temperatures without compromising productivity. Liquid nitriding using appropriate chemicals, coupled with application-specific pre and post nitriding treatments/processes can deliver significant performance advantages.

ARCOR DT

- New low temperature nitriding technology facilitates maximum nitriding kinetics at lower temperatures.

- Low temperature nitriding (500-525°C) preserves core hardness for treated components.

- In contrast, using traditional nitriding chemistries at lower temperatures leads to higher costs and greater waste.

ARCOR CS

- Post-nitriding impregnation treatments, using proprietary compounds, significantly enhance corrosion resistance. This is also a good option for compounds requiring low-friction run-in behavior.

|

ARCOR V |

ARCOR N |

ARCOR DT |

ARCOR CS |

| Friction properties |

+++ |

++ |

++ |

+++ |

| Wear resistance |

+++ |

+++ |

+++ |

+++ |

| Scuffing resistance |

+++ |

+++ |

+++ |

+++ |

| Corrosion resistance |

+++ |

+++ |

++ |

++++ |

| Bending resistance |

+ |

+++ |

+ |

+ |

Nitriding Treatments differ based upon:

- Choice of nitriding chemistry

- Processing temperature & time

- Cooling options

- Post-nitriding metal finishing and surface impregnation options

Bend Strength Enhancement with ARCOR® Liquid Nitrocarburizing

A hard and compact compound layer can significantly improve wear and corrosion resistance, but there is generally some tradeoff in terms of the ductility and the bend strength of the nitrocarburized component.

To address this tradeoff and achieve the right balance in properties, HEF’s ARCOR® Liquid Nitrocarburizing process can be tailored to meet demanding applications that require enhanced wear resistance with superior ductility. In certain scenarios, impact properties are also improved with this advanced technology.

The combination of the following metallurgical factors can result in a unique microstructure on the component surface, which contributes to enhanced bend strength:

- ARCOR® liquid nitrocarburizing chemistry

- Controlled processing temperature

- Specific steel grades – primarily certain plain carbon steels and low alloy steel

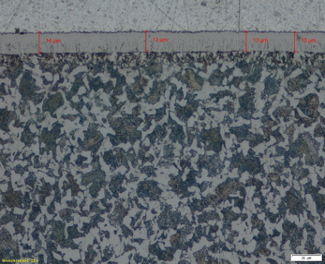

Microstructure of ARCOR® treated AISI 1045 steel

Some applications where significant performance improvements can be achieved with this optimized nitrocarburizing technology are:

- Piston rods for shock absorbers

- Gas springs

- Differential thrust washers

- Transmission half-shaft washers

- Hydraulic & pneumatic cylinders and shafts

- Miscellaneous shafts and pins where improved bend strength and enhanced ductility is required

To summarize, ARCOR® liquid nitrocarburizing technology can help enhance:

- Wear resistance

- Corrosion resistance

- Ductility

- Impact resistance

- Bending fatigue strength

In addition to these performance benefits, the nitriding duration with this optimized ARCOR® liquid nitrocarburizing is much shorter, resulting in faster turnaround times to our customers!

Please contact sales@hefusa.net for further information.