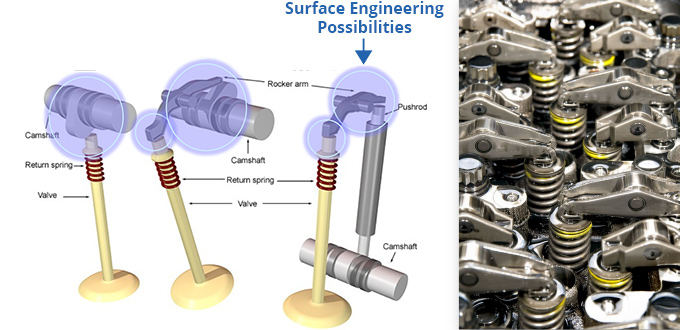

Valve Train Components

Up to 20% of the total friction losses in an engine can be attributed to the valve train. The high sliding velocities and contact pressures in mechanically complex valve train configurations such as VVT, coupled with the increasing number of contact points between components such as the cam, tappets, lash adjustors, push-rods, rocker-arms, rollers etc. are sources of additional parasitic friction. To minimize fiction losses at contact interfaces, the recent trend has been to use DLC coatings that can reduce the coefficient of friction by as much as 60-70% compared to uncoated surfaces.

Bucket Tappets

The interface between the cam lobe and the flat top-surface of a bucket tappet generates a high level of friction. Applying an appropriate DLC coating on the tappet surface can reduce friction forces by up to 66% and DLC on both the cam lobe and tappet can reduce this friction even further. Compared to coating the entire cam shaft, assembled cam lobes can be DLC coated economically. It is expected that by 2020, 35% of all tappet manufactured globally will be DLC coated.

Rocker Arms / Finger Followers

HEF's family of DLC based CERTESS coatings are also ideal for reducing rocker arm friction. DLC coated steel roller pins not only perform better than bronze pins in terms of improved wear resistance and lower friction, the elimination of bronze results is an overall lower cost option.

DLC coated Roller pin:

- Lower friction (sliding to rolling) and wear

- Switch from bronze pin to DLC coated steel pin